Dirección:

No.233-3 Yangchenghu Road, Parque Industrial Xixiashu, Distrito Xinbei, Ciudad de Changzhou, Provincia de Jiangsu

• La alta precisión y la alta eficiencia pueden lograr una superficie de procesamiento de alta calidad de los electrodos de cobre.

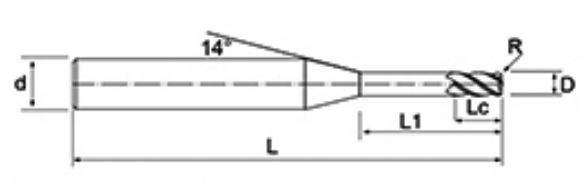

| No. | reiámetro D | Ángulo R R | longiture de la flauta lc | Longitud efectiva L1 | Longitud total L | Diámetro del vástago d | Recuento de cuchillas f |

| NNX-4RSP-D1-L4 | 1 | 0.1 | 1.5 | 4 | 50 | 4 | 2 |

| NNX-4RSP-D1-L6 | 1 | 0.1 | 1.5 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1-L8 | 1 | 0.1 | 1.5 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1-L10 | 1 | 0.1 | 1.5 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1-L12 | 1 | 0.1 | 1.5 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1-L14 | 1 | 0.1 | 1.5 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1-L16 | 1 | 0.1 | 1.5 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1-L18 | 1 | 0.1 | 1.5 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1-L20 | 1 | 0.1 | 1.5 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D1-L4 | 1 | 0.2 | 1.5 | 4 | 50 | 4 | 2 |

| NNX-4RSP-D1-L6 | 1 | 0.2 | 1.5 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1-L8 | 1 | 0.2 | 1.5 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1-L10 | 1 | 0.2 | 1.5 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1-L12 | 1 | 0.2 | 1.5 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1-L14 | 1 | 0.2 | 1.5 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1-L16 | 1 | 0.2 | 1.5 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1-L18 | 1 | 0.2 | 1.5 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1-L20 | 1 | 0.2 | 1.5 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L6 | 1.5 | 0.1 | 2.3 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L8 | 1.5 | 0.1 | 2.3 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L10 | 1.5 | 0.1 | 2.3 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L12 | 1.5 | 0.1 | 2.3 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L14 | 1.5 | 0.1 | 2.3 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L16 | 1.5 | 0.1 | 2.3 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L18 | 1.5 | 0.1 | 2.3 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L20 | 1.5 | 0.1 | 2.3 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L6 | 1.5 | 0.2 | 2.3 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L8 | 1.5 | 0.2 | 2.3 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L10 | 1.5 | 0.2 | 2.3 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L12 | 1.5 | 0.2 | 2.3 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L14 | 1.5 | 0.2 | 2.3 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L16 | 1.5 | 0.2 | 2.3 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L18 | 1.5 | 0.2 | 2.3 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L20 | 1.5 | 0.2 | 2.3 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D2-L6 | 2 | 0.1 | 3 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D2-L8 | 2 | 0.1 | 3 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D2-L10 | 2 | 0.1 | 3 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D2-L12 | 2 | 0.1 | 3 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D2-L14 | 2 | 0.1 | 3 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D2-L16 | 2 | 0.1 | 3 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D2-L18 | 2 | 0.1 | 3 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D2-L20 | 2 | 0.1 | 3 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D2-L6 | 2 | 0.2 | 3 | 6 | 50 | 4 | 4 |

| NNX-4RSP-D2-L8 | 2 | 0.2 | 3 | 8 | 50 | 4 | 4 |

| NNX-4RSP-D2-L10 | 2 | 0.2 | 3 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D2-L12 | 2 | 0.2 | 3 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D2-L14 | 2 | 0.2 | 3 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D2-L16 | 2 | 0.2 | 3 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D2-L18 | 2 | 0.2 | 3 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D2-L20 | 2 | 0.2 | 3 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D2-L6 | 2 | 0.5 | 3 | 6 | 50 | 4 | 4 |

| NNX-4RSP-D2-L8 | 2 | 0.5 | 3 | 8 | 50 | 4 | 4 |

| NNX-4RSP-D2-L10 | 2 | 0.5 | 3 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D2-L12 | 2 | 0.5 | 3 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D2-L14 | 2 | 0.5 | 3 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D2-L16 | 2 | 0.5 | 3 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D2-L18 | 2 | 0.5 | 3 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D2-L20 | 2 | 0.5 | 3 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L10 | 3 | 0.1 | 4.5 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.1 | 4.5 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.1 | 4.5 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.1 | 4.5 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.1 | 4.5 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.1 | 4.5 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L10 | 3 | 0.2 | 4.5 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.2 | 4.5 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.2 | 4.5 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.2 | 4.5 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.2 | 4.5 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.2 | 4.5 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L10 | 3 | 0.5 | 4.5 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.5 | 4.5 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.5 | 4.5 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.5 | 4.5 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.5 | 4.5 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.5 | 4.5 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.2 | 4.5 | 12 | 60 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.2 | 4.5 | 14 | 60 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.2 | 4.5 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.2 | 4.5 | 18 | 60 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.2 | 4.5 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.2 | 4.5 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.5 | 4.5 | 12 | 60 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.5 | 4.5 | 14 | 60 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.5 | 4.5 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.5 | 4.5 | 18 | 60 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.5 | 4.5 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.5 | 4.5 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.2 | 4.5 | 12 | 75 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.2 | 4.5 | 14 | 75 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.2 | 4.5 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.2 | 4.5 | 18 | 75 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.2 | 4.5 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.2 | 4.5 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D3-L30 | 3 | 0.2 | 4.5 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.5 | 4.5 | 12 | 75 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.5 | 4.5 | 14 | 75 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.5 | 4.5 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.5 | 4.5 | 18 | 75 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.5 | 4.5 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.5 | 4.5 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D3-L30 | 3 | 0.5 | 4.5 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 0.2 | 6 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.2 | 6 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.2 | 6 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 05 | 6 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.5 | 6 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.5 | 6 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 0.2 | 6 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.2 | 6 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.2 | 6 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D4-L30 | 4 | 0.2 | 6 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D4-L35 | 4 | 0.2 | 6 | 35 | 75 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 0.5 | 6 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.5 | 6 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.5 | 6 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D4-L30 | 4 | 0.5 | 6 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D4-L35 | 4 | 0.5 | 6 | 35 | 75 | 6 | 4 |

| Serie ree herramientas | reiámetro | Radio | Radio de esquina | longitud de la flauta | longitud efectiva | Longitud total | reiámetro del vástago | |||

| D | R | CR | lc | L1 | L | d | ||||

| Fresas de carburo NNX para electrodo de cobre | D0.1~D0.9 | 0 -0.005 | R0.05~R2 | /-0.005 | CR0.05~CR0.5 | /-0.005 | 0 0.3 | 0 0.3 | 0.5 -0,5 | h5 |

| D1~D3.5 | 0 -0.005 | |||||||||

| D4~D10 | -0.003 -0.015 | R3~R5 | /-0.005 | CR1.0~CR3.0 | /-0.008 | 0 0.5 | 0 0.5 | |||

| D12~D20 | -0.003 -0.018 | R6~R10 | /-0.008 | |||||||

Las fresas de punta redonda de ranura profunda de 4 flautas NNX-4RSP para mecanizado de electrodos de cobre ofrecen una amplia gama de opciones de tamaño, desde diámetro pequeño hasta diámetro grande, desde longitud de borde corto hasta longitud de borde largo; cada especificación está cuidadosamente diseñada para satisfacer las necesidades de diferentes condiciones de trabajo. Ya sea que se trate de procesamiento fino o corte de áreas grandes, la combinación flexible de diferentes submodelos permite a los usuarios elegir libremente la herramienta más adecuada para lograr un procesamiento de electrodos de cobre eficiente y preciso.

El diseño especial de punta redonda de ranura profunda no solo mejora la rigidez de la herramienta, sino que también optimiza la distribución de la fuerza del filo, reduciendo efectivamente la vibración y las rebabas durante el procesamiento. El exclusivo diseño de ranura reduce la resistencia al corte, garantiza un corte estable de materiales de electrodos de cobre a altas velocidades y mejora el acabado de la superficie.

La herramienta utiliza un sustrato de partículas ultrafinas (0,2 μm) con la última tecnología de recubrimiento DLC, que tiene una excelente resistencia al desgaste y un coeficiente de fricción extremadamente bajo, lo que la hace particularmente superior en el procesamiento de electrodos de cobre. Combinado con la tecnología de rectificado ultrafino y la hoja de rugosidad ultrabaja, reduce en gran medida el problema de adhesión de la herramienta y mejora la vida útil y la consistencia del procesamiento.

Establecimiento de empresa

Empleados

Changzhou Maton Tools Co.,Ltd. is located in the economically developed Yangtze River Delta region.The factory is located in XixiashuHigh-tech Development Zone,a well-known tool town in China. We are Fresas de extremo redondo de ranura profunda de 4 flautas para mecanizado de electrodos de cobre Suppliers.

Magotantools take the ISO9001 quality system as the standard,under the guidanceof the business philosophy of"zero defect in products"and"zero distance in service",based on the spirit of"integrity","unity"and"exploita- tion",and follow a fair and just company style for management.Product production adopts five-axisand six-axis CNC grinding and machining centers from Germany,Switzerland,Japan,etc.,and is equipped with high-precision testing equipment such as Germany,Japan,and China,so as to meet the needs of production with high quality and quantity.

The company continuously develops various high-performance CNC tools, and has won various national awards. Professional Fresas de extremo redondo de ranura profunda de 4 flautas para mecanizado de electrodos de cobre Factory. More than 10 patents,the company's products are mainly used in the defense industry, aerospace industry,automotive industry,electronic products and molds and other fields.

The company's various products are recognized and favored by well-known domestic companies.With infinite technology,infinite creation,and pursuit of excellence,Magotan tools will write future prosperity and dreams with more extraordinary confidence and high-quality quality.

Le responderemos dentro de las 12 horas posteriores a la recepción de la consulta de lunes a viernes.

Somos fabricantes, producimos y vendemos nosotros mismos.

We mainly produce tungsten steel milling cutters, drill bits and other hard alloy tools. Professional Fresas de extremo redondo de ranura profunda de 4 flautas para mecanizado de electrodos de cobre Suppliers.

Nuestros productos cubren casi toda la industria del molde, industria de defensa, industria aeroespacial, industria automotriz, productos electrónicos y otros campos.

Yes, our main focus is on customized products. We develop and produce products based on the drawings or samples provided by customers. Custom Fresas de extremo redondo de ranura profunda de 4 flautas para mecanizado de electrodos de cobre.

We have over 30 units of WALTER from Germany, Makino from Japan, ROLLMATIC from Switzerland, and TTB from Switzerland, with an annual output value of 80 million RMB. We are Fresas de extremo redondo de ranura profunda de 4 flautas para mecanizado de electrodos de cobre Factory

En primer lugar, después de cada proceso, realizamos las inspecciones correspondientes. Para el producto final, realizaremos una inspección completa al 100% de acuerdo con los requisitos del cliente y los estándares internacionales;

Luego, contamos con equipos de prueba avanzados y completos de primer nivel en la industria, como analizadores espectrales, microscopios metalográficos, etc., que pueden garantizar la estabilidad y consistencia de las herramientas de corte, al tiempo que cumplen con los requisitos de prueba de alta precisión de las herramientas de corte de los clientes.

Al cotizar, confirmaremos con usted el método de transacción, FOB, CIF, CNF u otras opciones. Cuando producimos al por mayor, generalmente hacemos primero un pago por adelantado del 30% y luego pagamos el saldo restante al presentar el conocimiento de embarque. Utilizamos principalmente T/T como método de pago, pero L/C también es aceptable.